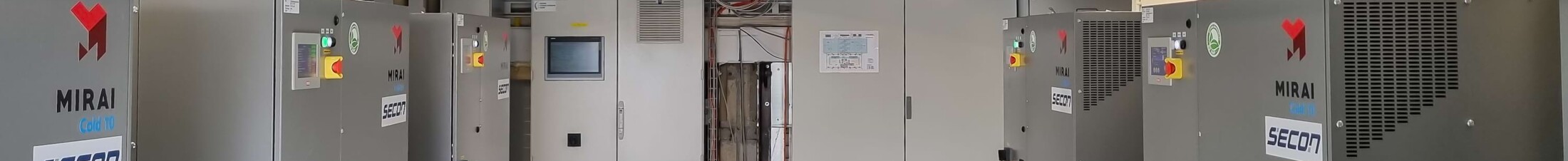

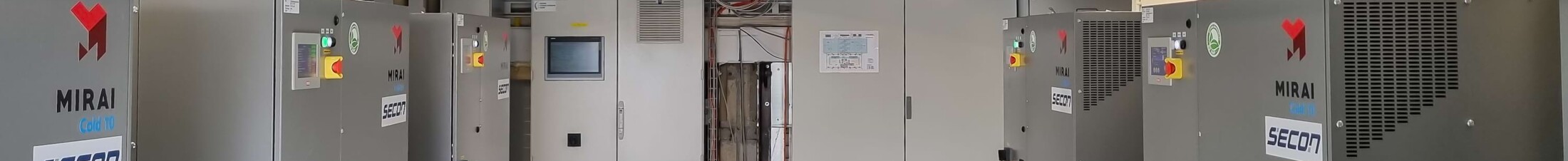

The Mirai Intex cold air refrigeration technology works oil-free with only air as a refrigerant. To do this, Mirai Intex has developed a unique turbo compressor expander. This is air-bearing and the compressor and expansion wheel (expander) are on one shaft, so that the energy of the expansion of the compression is fed back. The turbo compressor-expander unit is designed with air bearings, so that no oil is required. With the frequency converter control, any temperature can be controlled and regulated to an accuracy of 0.5 K. As standard, the machines can regulate any temperature from -30°C to -110°C. In special versions, the range can be extended down to -160°C with air as the refrigerant. The pressures in the open machines are a maximum of 1 bar, which is less than the pressure of a bicycle tire.

Air as a refrigerant is free, non-hazardous and free from regulations.

Air as refrigerant / No refilling required / Environmentally friendly

No oil in the system thanks to air bearings / Lower costs

Compliance with the law Compliance with all international standards/regulations

Stable cooling performance when operating with cooling water

No chemical substances / No fire or explosion hazard

No vibration and greatly reduced Noise / Turbo engine design reduces noise and vibration

One of the most common causes of failure of refrigeration systems is compressor damage caused by the entry of liquid refrigerant into the compressor or by insufficient lubrication, e.g. due to displaced oil or wear. Another common cause of failure is wear and tear from vibration, such as failure of small oil lines. In cascade systems for low-temperature applications, there is also the fact that several compressor circuits have to work simultaneously and influence each other. The cold air chillers have no phase change, no oil and, thanks to the air bearing, almost wear-free operation without vibration. This technology has a high level of reliability.

We carried out a detailed study of the energy efficiency of low-temperature refrigeration technology and were able to prove that cold-air refrigeration technology is highly efficient in the field of low-temperature technology. The detailed investigation can be found in our ULT report.