Our ULT containers are designed with the storage system, security, loading and unloading concepts in line with customer needs and the given space. They consist of special industrial panels with PU foam filling, with optionally integrated vacuum panels, which are mechanically stable enough for extreme temperatures and achieve an adequate insulating effect. For the low-temperature rooms, we use the flexible cold air chillers from Mirai Intex, which can flexibly achieve temperatures from -30°C to -110°C (optionally up to -160°C). Appropriate lock systems are integrated for energy optimization and ice mist reduction.

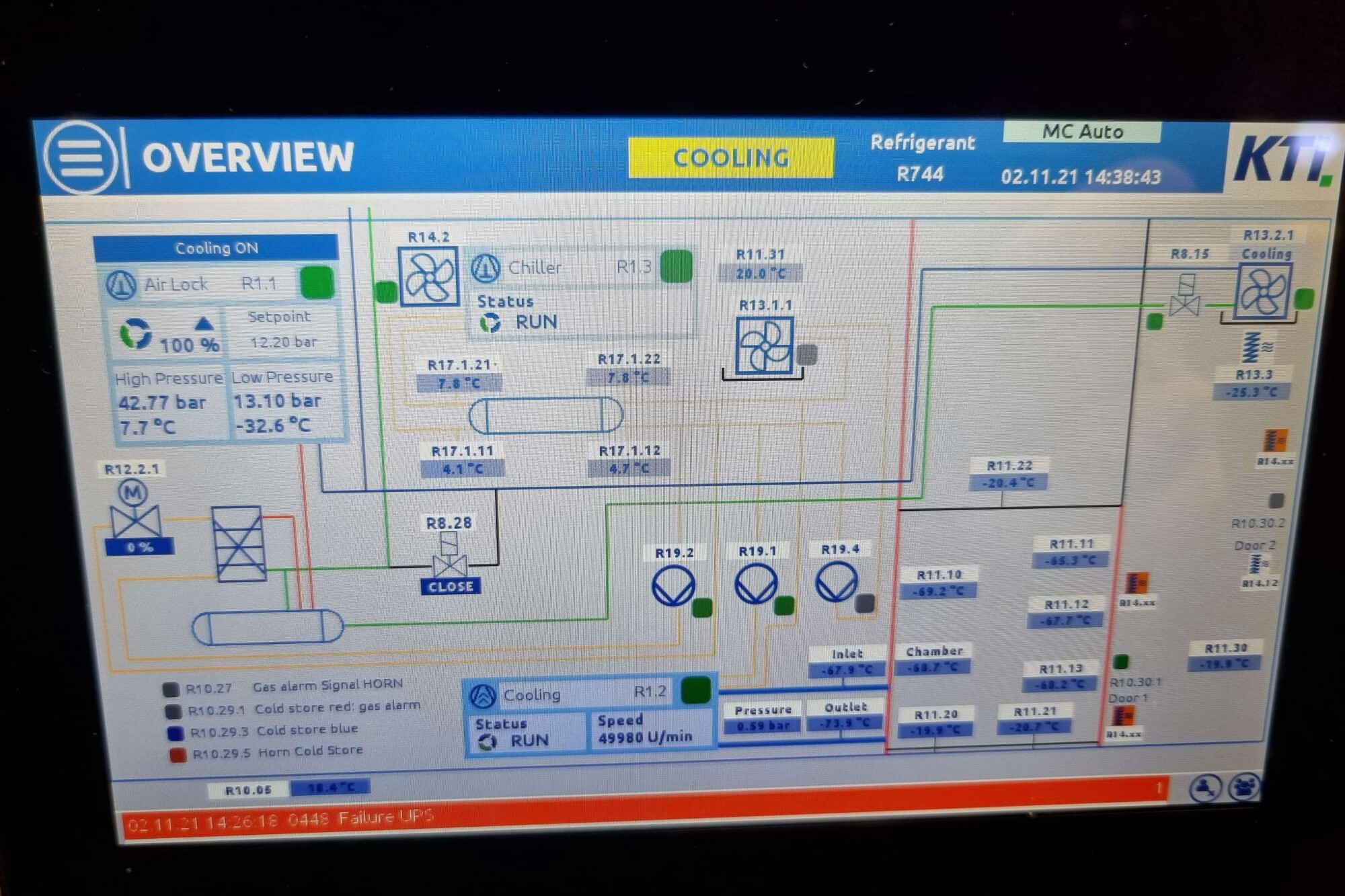

The machine control is implemented with an S7 and our developed security concepts and can be extended to customer needs, such as GMP Audit Trail with GAMP5. The equipment in the storage rooms is integrated, from temperature monitoring and LED lighting to shelving and rail systems.