Turnkey, individual low-temperature transport trailers with air (R729) as the refrigerant for flexible use from −40°C to −110°C

Planned and implemented to suit your requirements.

Turnkey, individual low-temperature transport trailers with air (R729) as the refrigerant for flexible use from −40°C to −110°C

Planned and implemented to suit your requirements.

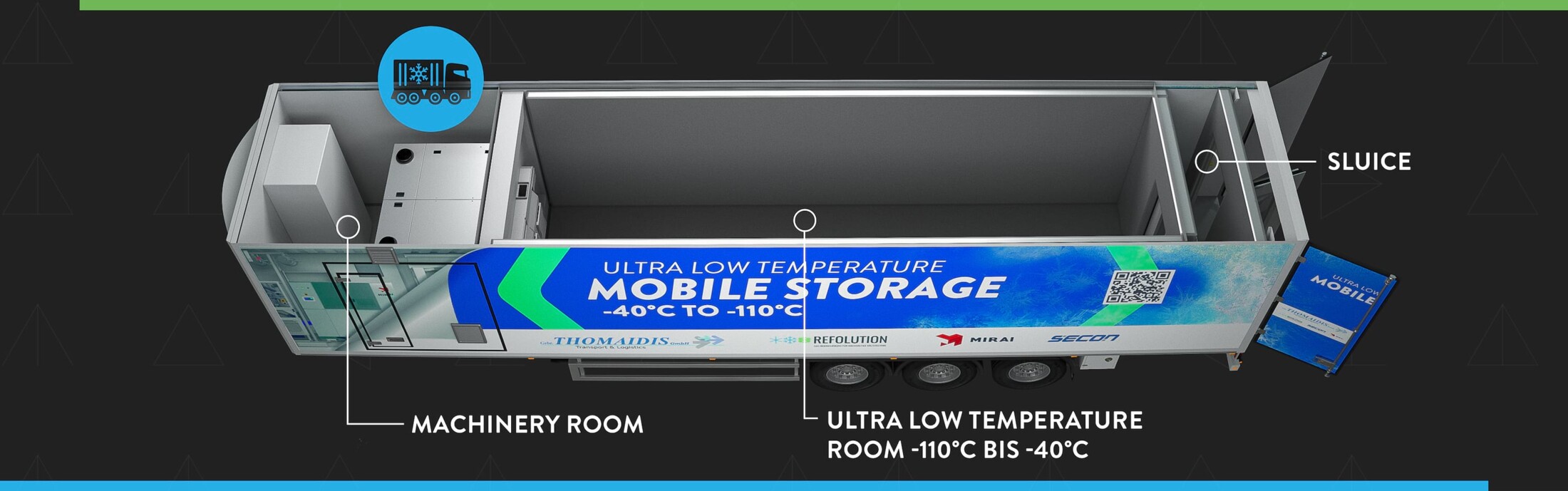

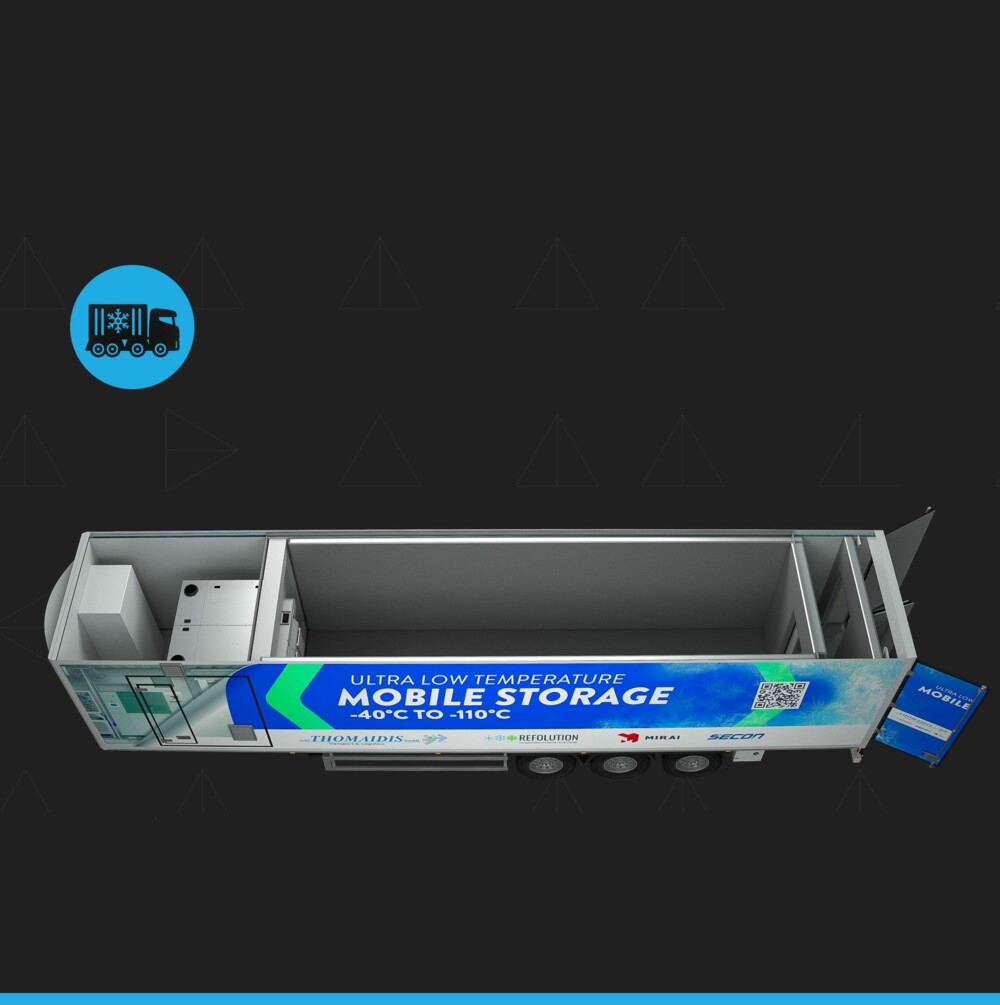

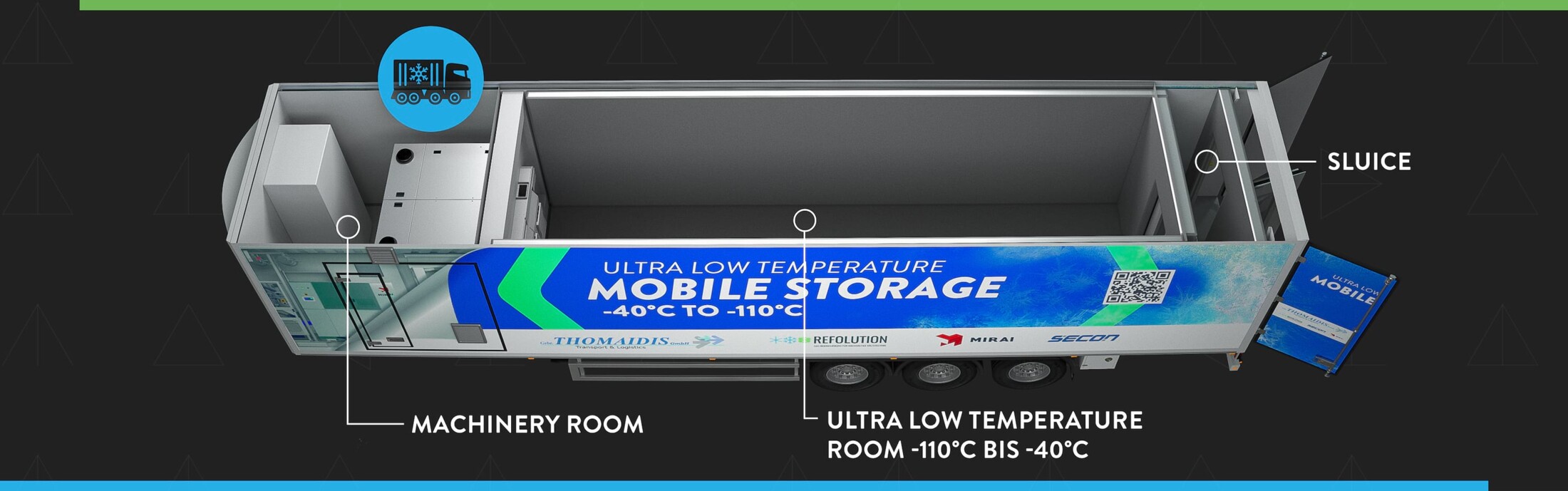

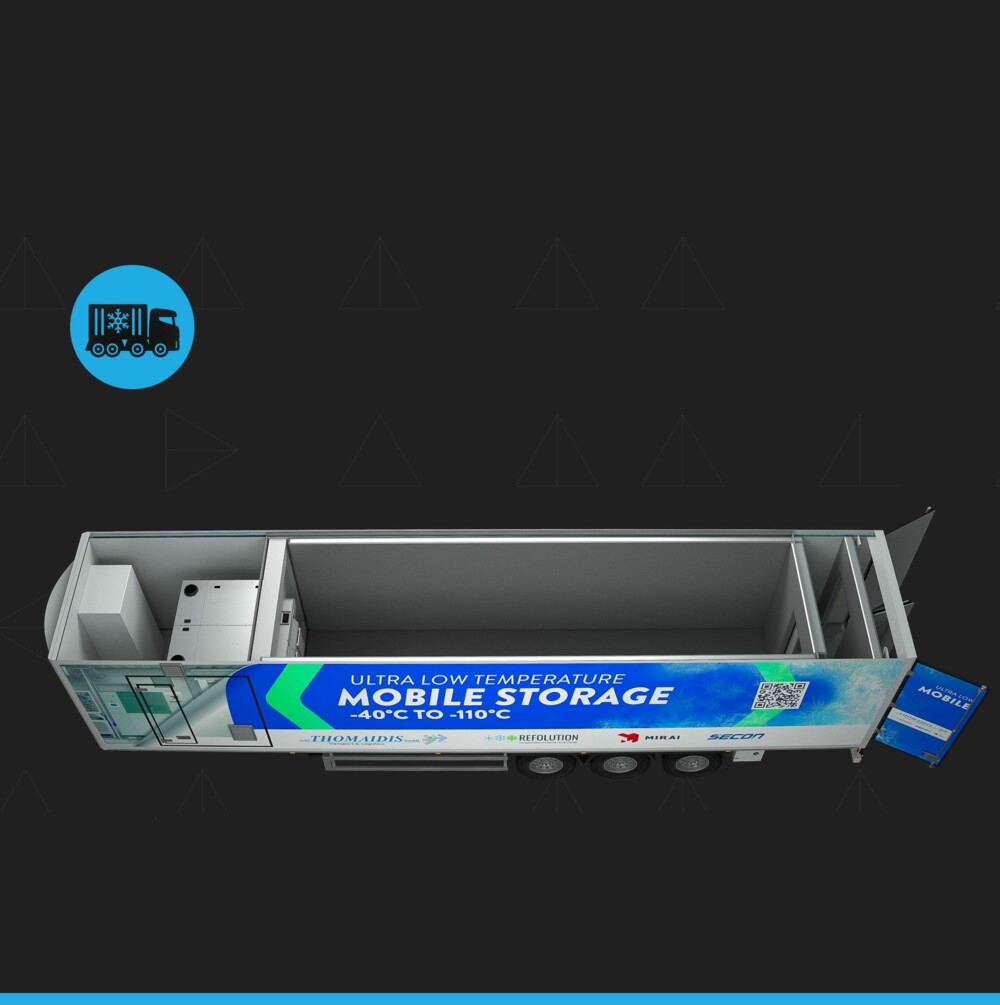

The CryoCargo110 is a high-quality mobile low-temperature warehouse, including storage system, safety, loading and unloading concept.

The trailer consists of special insulating panels with PU foam, which are mechanically stable enough for extreme temperatures and achieve an adequate insulating effect for the low-temperature range.

For the main storage room, we used the flexible cold air chillers from Mirai Intex, which achieve temperatures from -40 to -110°C (optionally up to -160°C). Appropriate lock systems are integrated for energy optimization and ice mist reduction.

The machine control is implemented with an S7 and our developed security concepts and can be extended to customer needs, such as GMP Audit Trail with GAMP5. The equipment of the CryoCargo 110 is integrated from temperature monitoring to LED lighting to shelf or rail systems.

The insulation is realized with proven polyurethane insulation elements. Depending on the requirements, these can be optimized with integrated vacuum plates. When cold, the elements contract and the outer shell stays warm. This leads to mechanical stress, which is greater the higher the temperature difference and the higher the chamber. Our chambers are reinforced with hook and loop fasteners, so the chambers remain mechanically stable even after many temperature changes. In addition, we check all our installations with the thermal imaging camera and thus optimize penetrations, such as for cable bushings.

Tried and tested low-temperature LEDs are used for lighting, which illuminate the room well, introduce a low heat load into the storage room and thus greatly reduce operating costs. In addition, these are battery-buffered so that the room can be left safely even in the event of a power failure.

The turnkey solution is controlled by an industry-proven S7 1200 (Siemens).

Optionally, the system can be equipped and tracked with predictive maintenance software. This also increases reliability, and the trailer can also be equipped with a replacement control and audit trail (GAMP 5). The control can be integrated into the building management system (GLT) with the classic interfaces. In addition, if necessary, faults can be detected and rectified at an early stage via remote maintenance.

The machine room is located in the rear part of the trailer.

The cold air machine, the intake ducts, the switch cabinets for control and

Control of the storage room and its components and another refrigeration system for cooling

of the engine room. This ensures operation even at above-average temperatures

outside temperatures and keeps the machine room at a constant 25°C.

Reliable, durable, efficient and safe for people and the environment!

The safety concept includes a dead man's switch, a battery buffer for the lighting and a non-slip floor. The dead man's switch is a proven concept to ensure personnel safety and can optionally be combined with your factory security

or control room can be connected.

The lock system limits the ambient air and the moisture that can enter the

Main storage room is introduced during loading and unloading. With which we achieve a clear view in the storage room and greatly reduce the formation of ice fog and ice, thereby ensuring safe handling for the staff.

We carry out a detailed cooling load calculation with your requirements and then use the appropriate, efficient refrigeration technology with only natural refrigerants. For the low temperature below -40°C, the cold air cooling technology from Mirai Intex with only air (R729) is used in the open version. With its mechanical de-icing, this ensures a homogeneous temperature distribution, dry storage air with a dew point reduction of up to +20°C and constant temperatures without defrosting cycles.

Natural refrigerants are free from political regulations such as the F-Gas Regulation.

The trailer only needs diesel to ensure cooling during transport, with which two redundant diesel generators are operated. Optionally, it is possible to switch to terrestrial power connection during the stand. A power connection of 400 V/ 63 A is required for this.

The CryoCargo110 is a cryogenic trailer that includes a storage system with safety, loading and unloading concepts. The trailer consists of insulating panels with PU foam, which are mechanically stable enough for extreme temperatures.

In order to achieve temperatures of -40 °C to -110 °C (optionally to -160 °C) in the main storage room, we only use air as a refrigerant.

An airlock system is integrated to ensure energy optimisation and ice fog reduction and to allow access to the main storage room. The main task of the passively cooled airlock is to limit the exchanged air volume between the ambient air and the main storage room.

Individual design of the warehouse, locks and loading area.