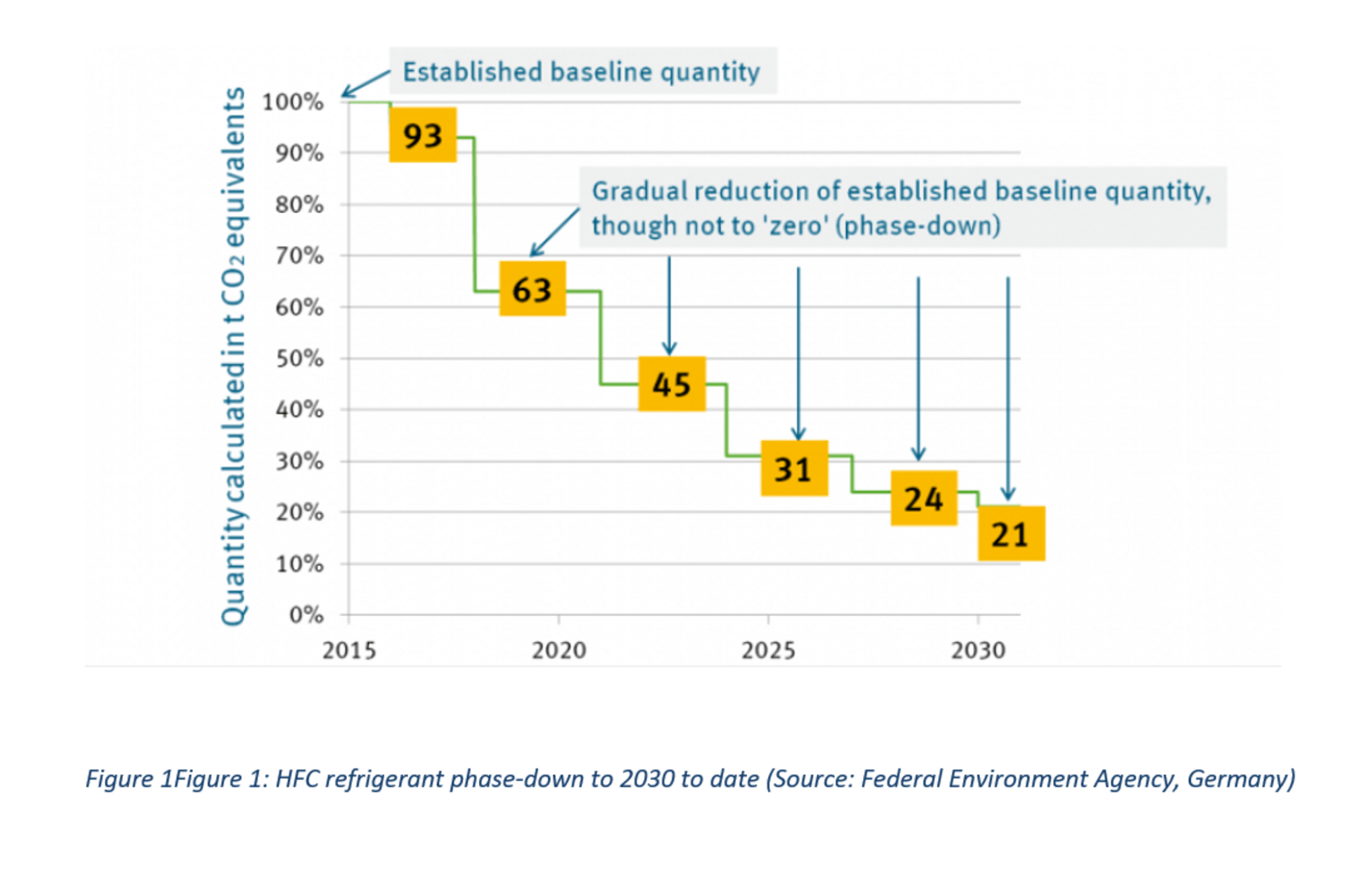

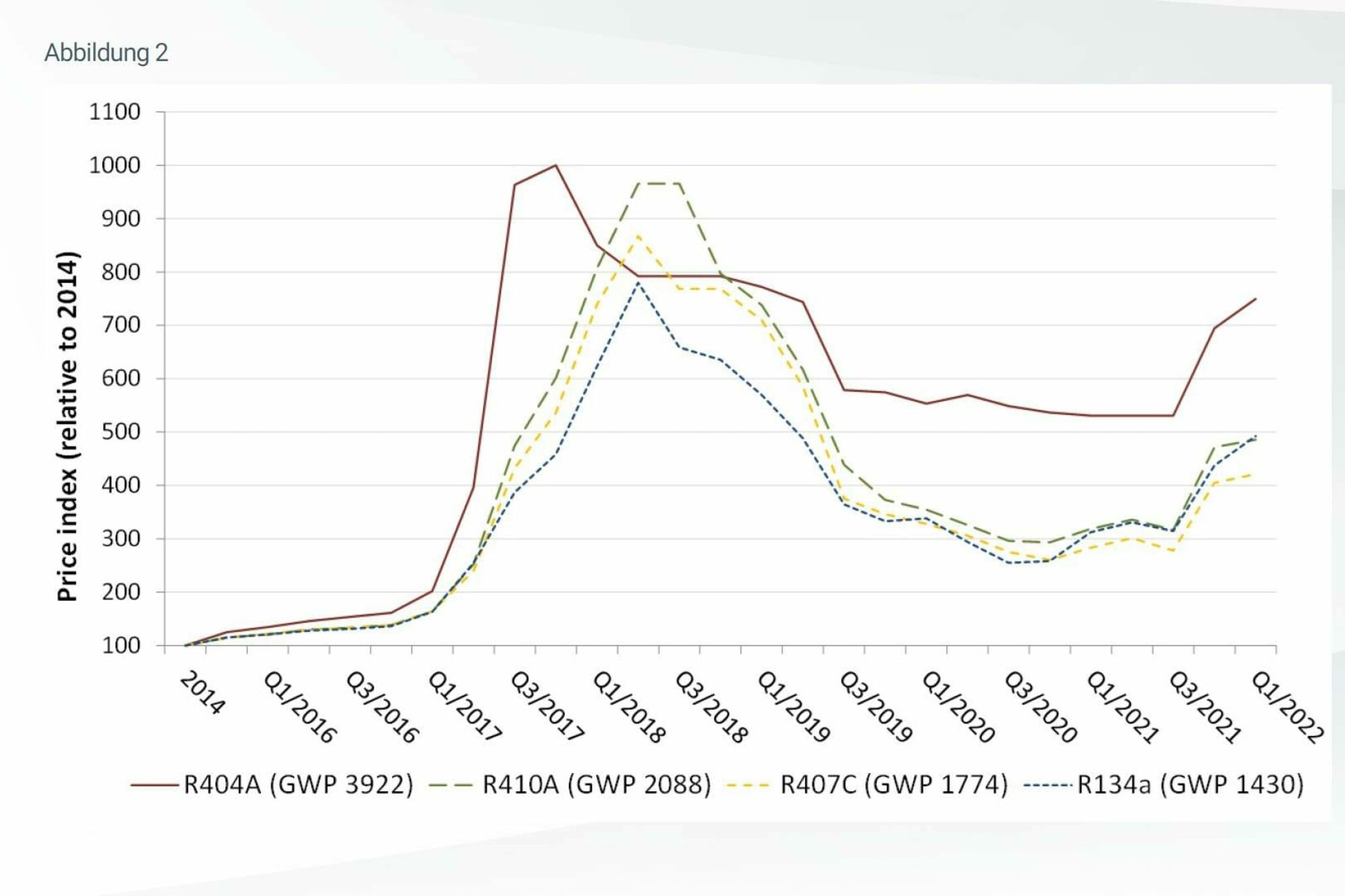

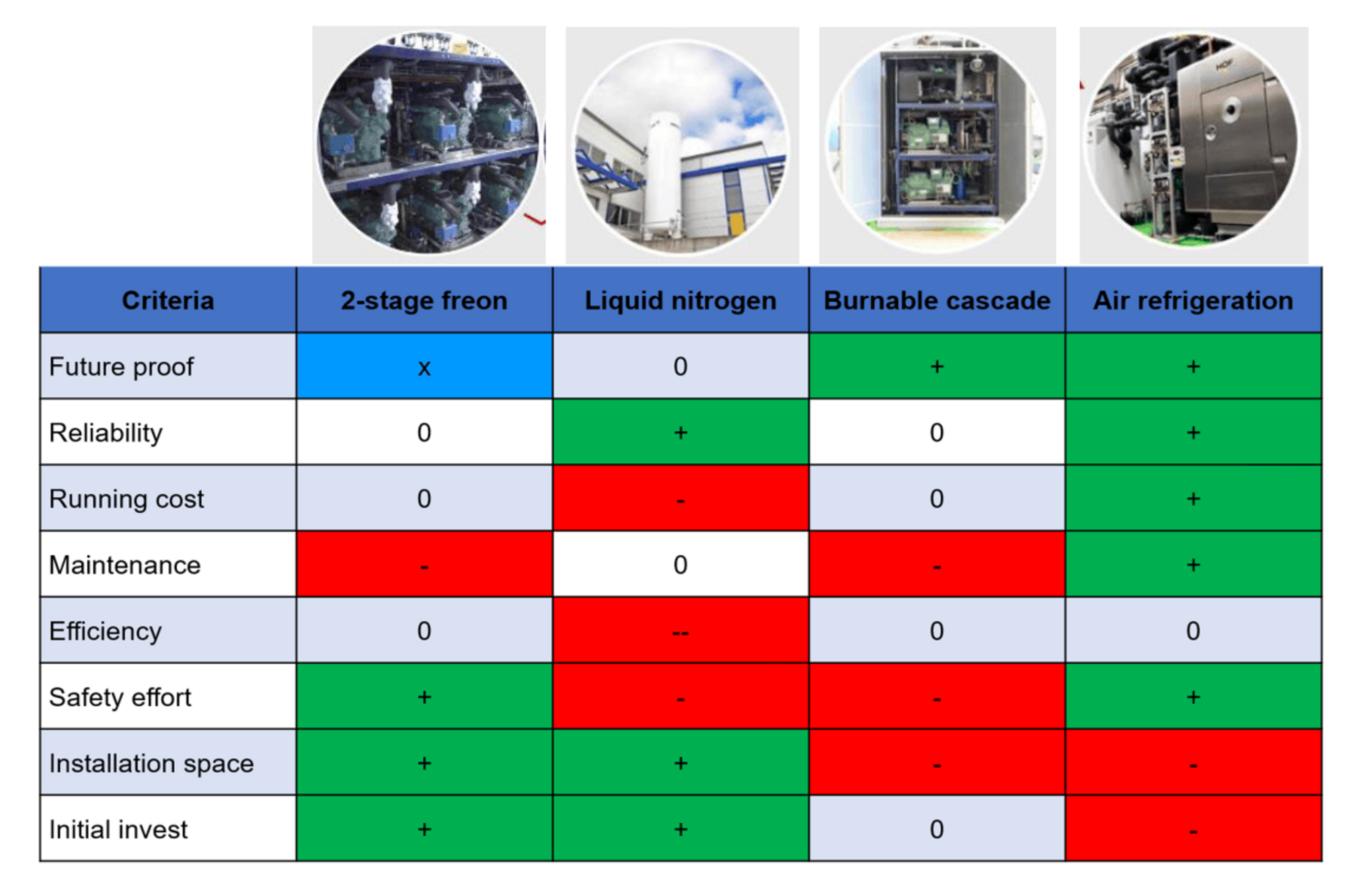

Due to the refrigerants used (e.g. R404A, R410A, R499A, R23), the majority of refrigeration systems for low-temperature technology are subject to the EU F-Gas Regulation. Currently, high GWP refrigerants are permitted until at least 2030 due to the exception of Article 13 of the F-Gas Regulation. Due to climate policy goals, operators will be faced with further restrictions on the use of refrigeration systems with a high GWP in the coming years. Among other things, the -50 °C exception when using high GWP refrigerants is increasingly being criticized and possible phase-downs are being proposed. In order to continue to ensure production reliability, strategic decisions must be made at an early stage and investments must be made in future-proof technologies. Anyone who is currently investing in new systems and retrofits with a high GWP (e.g. R452A) runs the risk of no longer being able to operate their systems after 2030, since either maintenance is prohibited or the availability of the refrigerants decreases sharply and the costs for maintenance increase significantly. In the long term, future-proof technologies will be solutions with natural refrigerants, because on the one hand they are environmentally friendly and efficient and on the other hand they are free of any regulations. For applications below -50 °C, cold air cooling technology and cascade systems with flammable refrigerants have become established and are already being used safely in many applications. In addition to new systems, the existing systems must also be considered. Many systems can be equipped with a retrofit of the refrigeration side without changing the actual process.