Low-temperature central refrigeration systems from -40°C to -110°C for demanding processes such as freeze drying.

Low-temperature central refrigeration systems from -40°C to -110°C for demanding processes such as freeze drying.

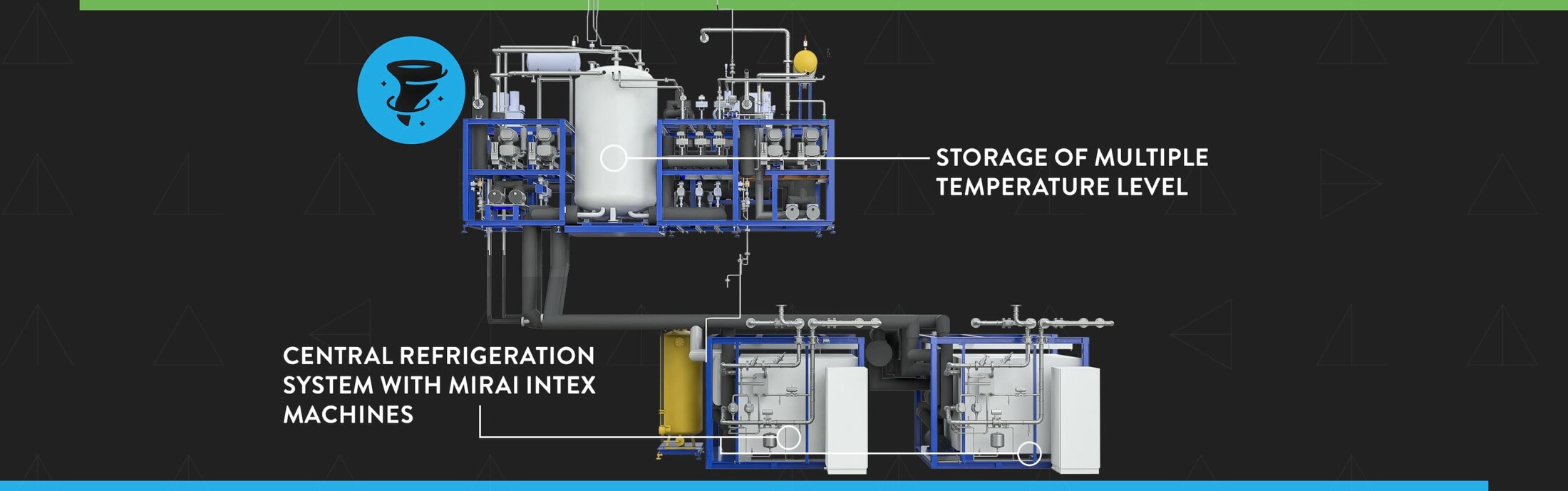

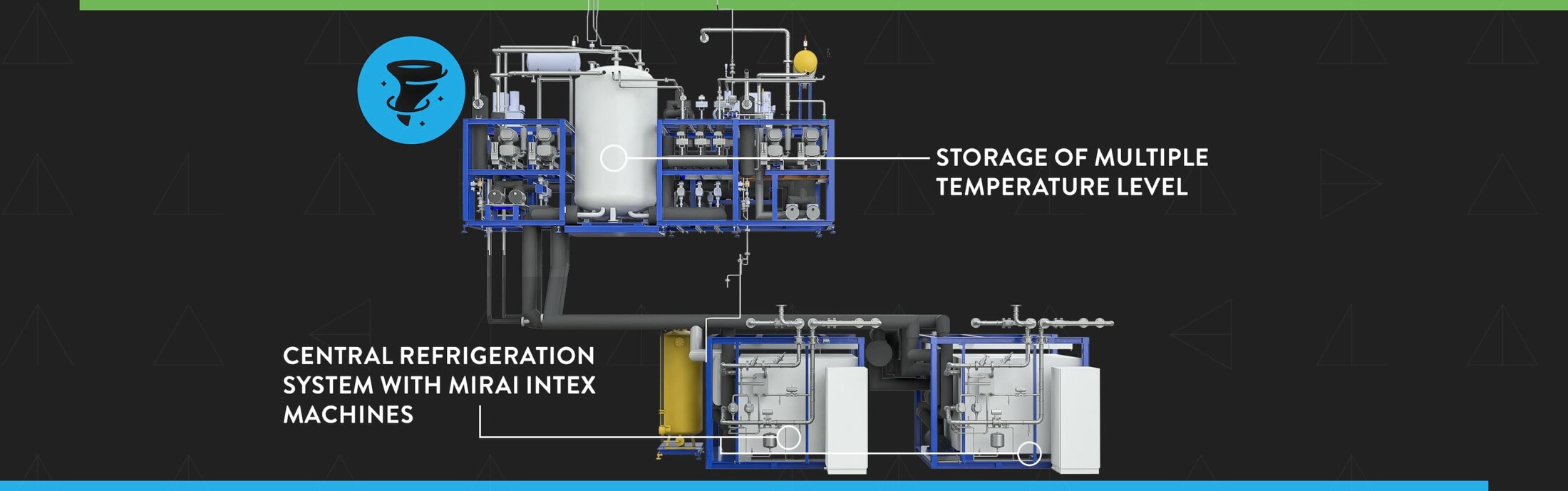

The central refrigeration system is essentially a layered storage tank with a heat transfer medium that can store, load and provide different temperature levels in the different layers. This means that in process steps that require little power, this can be stored in the form of cold heat carrier and in process steps that require a lot of power, this can be accessed directly. Especially in batch processes such as freeze drying, this enables a high specific cooling capacity with significantly fewer chillers and a reduction in power peaks in the electricity and cold water network. The loading accumulator is able to load and unload different layers at the same time without mixing them thanks to a patented inner workings. For temperatures below -40°C, the stratified storage tank is optimally charged with the cold air chillers from Mirai Intex with only air as the refrigerant.

Thanks to a patented storage tank design, several cold generators can load the storage tank and generate different temperature levels. As a result, the chillers are always operated at the optimum operating point.

As on the refrigeration side of the storage tank, multiple consumers can be connected to the storage tank. Due to the different temperature levels, consumers can be supplied with cold at the same time as required at different temperature levels.

The layered tank separates the chillers from the consumption side and initially serves as a hydraulic switch. In addition, it has several zones with which different consumers can be supplied at different temperatures at the same time. Large capacities can be developed in the short term via storage layers. This reduces the performance of the cooling loops to be installed and peaks in the electricity and cold water network.

Reliable, durable, efficient and safe for people and the environment!

The proven cold air cooling technology from Mirai Intex is used for temperatures below -40°C. The is characterized in this area by high efficiency and reliability. Due to the refrigerant air (R729), the system is environmentally friendly and there are no restrictions and regulations such as the EU F-Gas regulation and REACH.

Air as a refrigerant is free, unregulated and safe. The systems are robust and specially built for low temperatures.

Proven technology - Made in Germany. Wear-resistant and redundant.

Individually adapted to the needs Version with freely selectable temperatures in operation with high power density.

Speed-controlled, energy storage with reduced load peaks in the electricity and cooling water network

Natural refrigerant without high pressures.

No leak test, air-bearing compressor = no wear, no oil. High quality system technology.

Further information follows...

More options will follow...