HOF CryoProPhase - cleaning and recovery of solvent-containing exhaust gases by means of cryogenic exhaust gas treatment flexibly designed according to customer requirements.

HOF CryoProPhase - cleaning and recovery of solvent-containing exhaust gases by means of cryogenic exhaust gas treatment flexibly designed according to customer requirements.

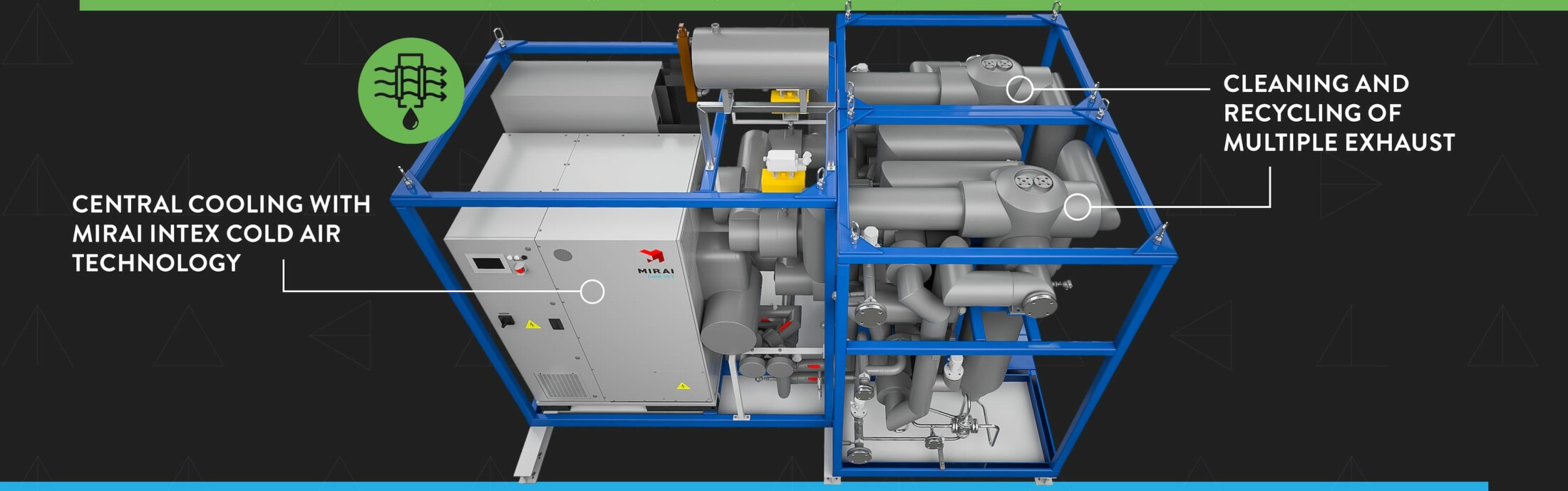

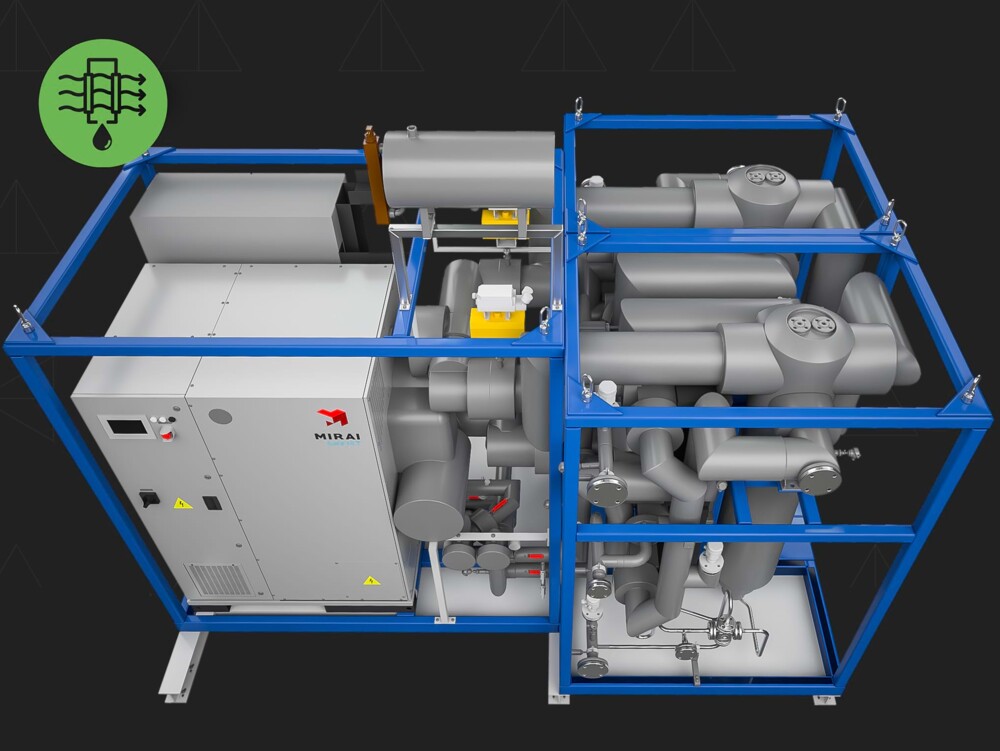

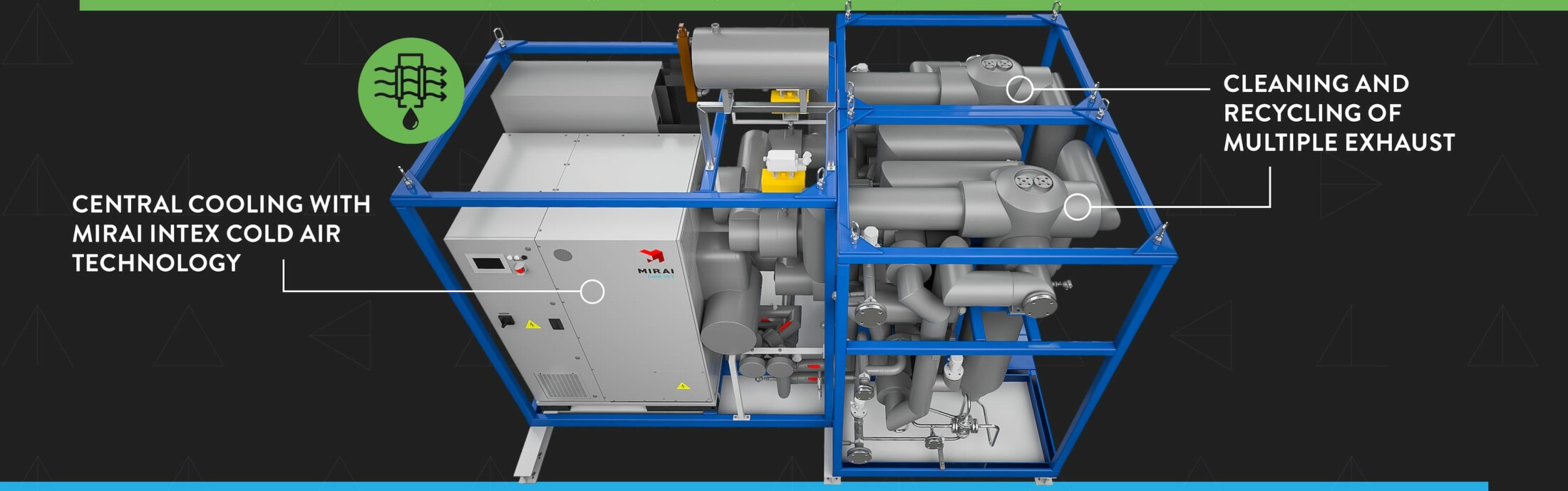

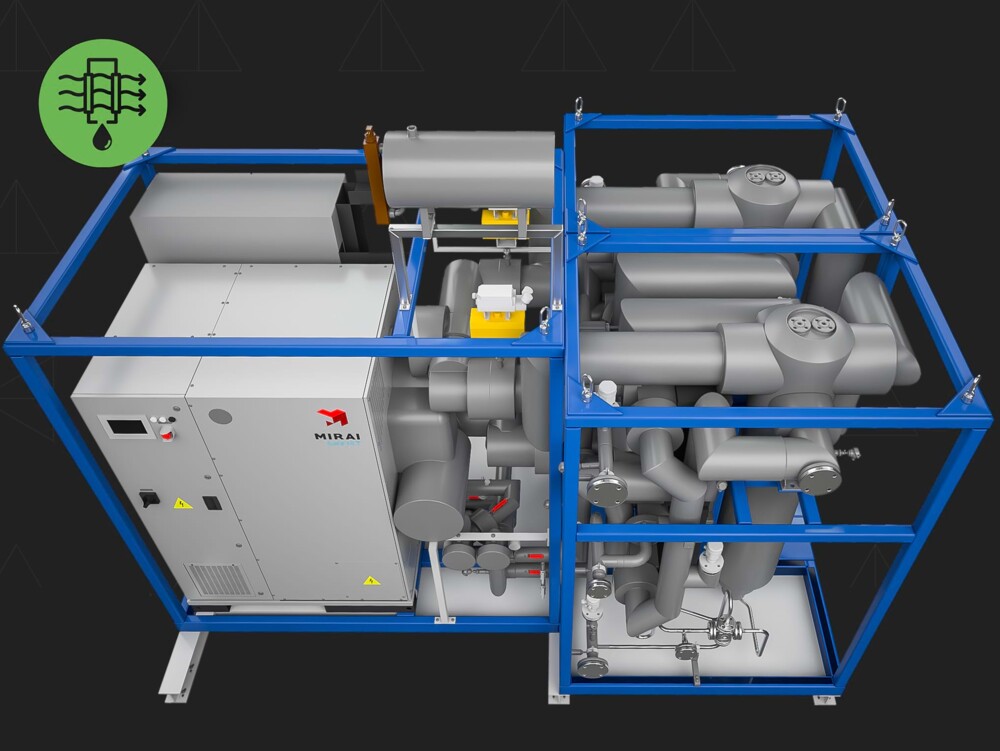

Together with our partner HOF Sonderanlagenbau GmbH, we have developed a new process for recycling solvents from waste gas flows. With the process, different solvents such as organic solvents ethanol, acetone and halogenated solvents dichloromethane can be condensed and recycled from one of several waste gas streams. In addition, the system can be equipped with special alternating heat exchangers and a regeneration cycle for moist exhaust gases. The cold is generated without liquid nitrogen using only natural refrigerants. The low temperature is achieved with the cold air cooling system from Mirai Intex.

In cryo-condensation, pollutants from the exhaust gas are condensed by cooling the exhaust system. After the process, the volatile components in the exhaust air flow are present as liquid condensate and can either be returned to the production process, cleaned or disposed of.

The cold air chiller from Mirai Intex enables large dynamic load changes with high efficiency thanks to the infinitely variable turbo compressor-expander unit. The required process temperatures can be flexibly set between -40 °C and -160 °C using the cold air chiller. The optimal condensation temperature can always be selected individually for different process conditions.

The CryoProPhase has a modular design, which allows the process to be designed flexibly and makes optimal use of installation space. For example, the process lines can be placed decentrally, while the cold is provided centrally by the cold air chillers.

Reliable, durable, efficient and safe for people and the environment!

Air as a refrigerant is always available and is not subject to any regulations

Flexible adjustment of the condensation temperature between -40 °C and -110 °C, optionally down to -160 °C

Refrigerant exclusively ambient air. Operating pressures up to a maximum of 10 bar overpressure

Oil and wear-free thanks to the air-bearing compressor-expander unit of the cold air chiller

Flexible process management and set-up possible thanks to the modular structure

Through refrigeration close to the useful temperature, efficient cold air refrigeration technology and energy recovery

High efficiency and compliance with limit values even under dynamic process conditions

Most of the exhaust gases can be fully recycled and reused

- Refrigerant air for low temperatures otherwise hydrocarbons or CO2

- Pressures of the cold air chiller up to a maximum of 10 barg

- Flexible setting of the condensation temperature between -40°C and -110°C (optionally down to -160°C)

- Low maintenance of the cold air chiller due to oil and wear-free, air-bearing compander unit

- Flexible use thanks to the modular structure

- High efficiency and compliance with limit values even under dynamic process conditions

- Efficiency through refrigeration close to the useful temperature, efficient refrigeration technology and energy recovery

- Most of the exhaust gases can be fully recycled and reused