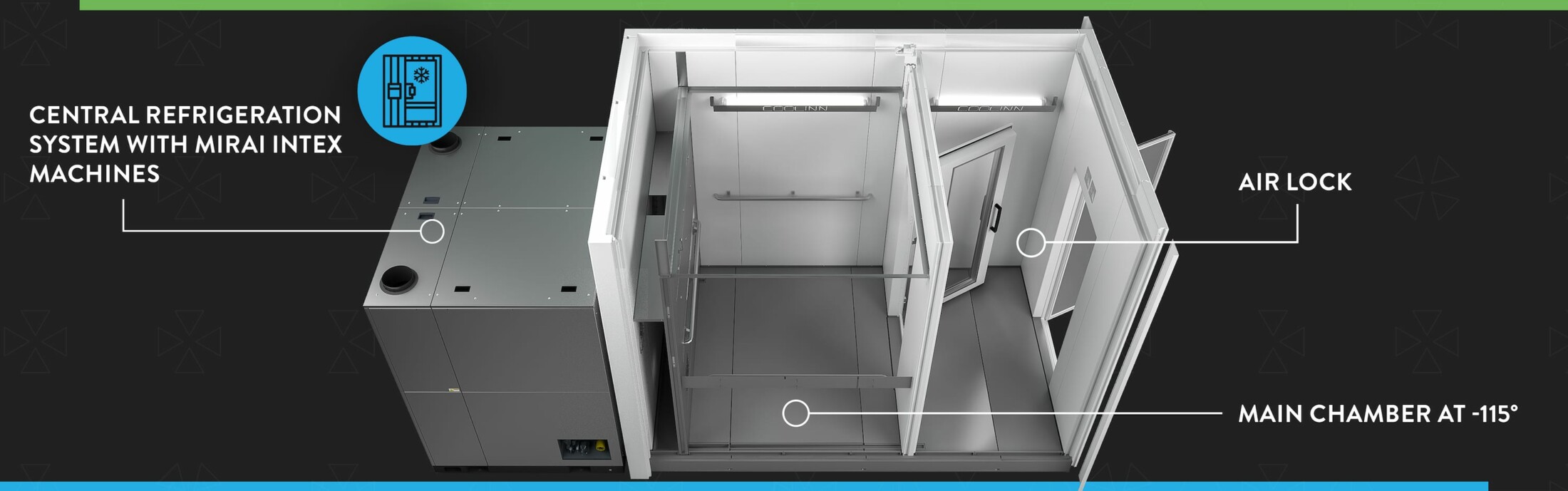

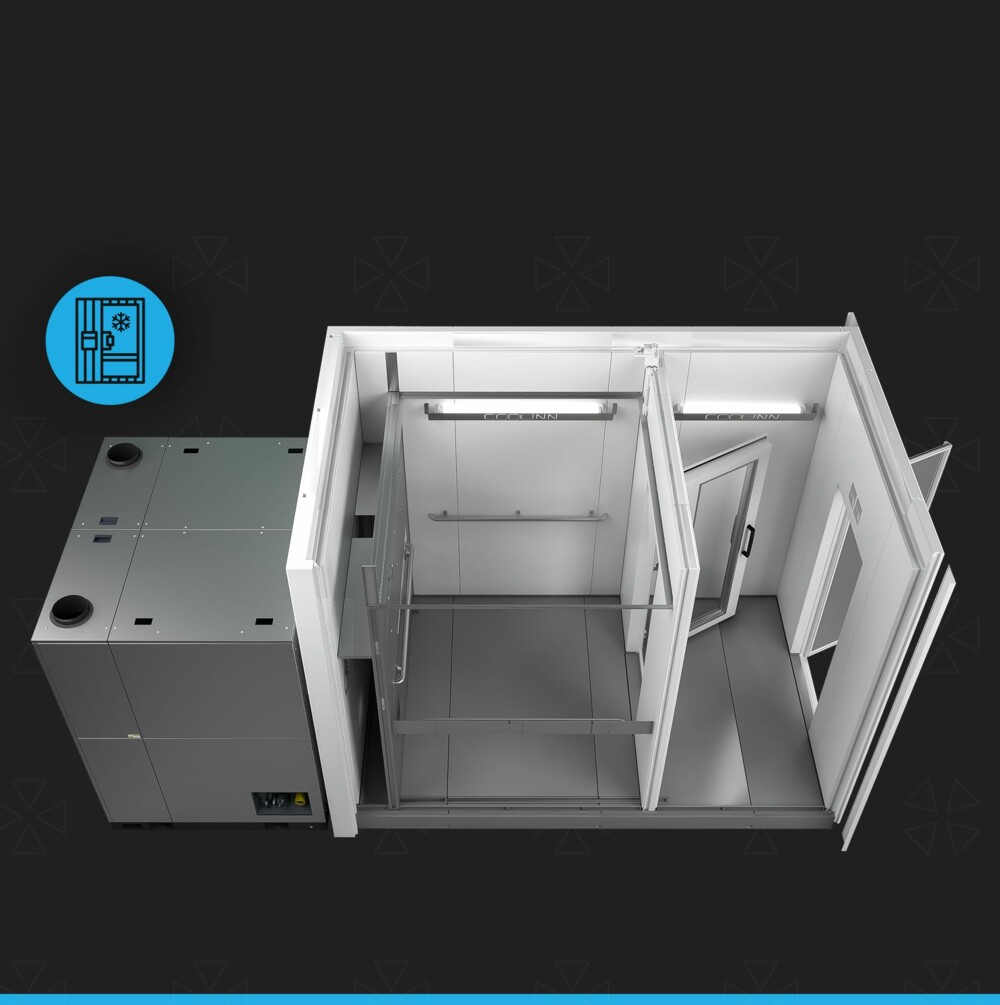

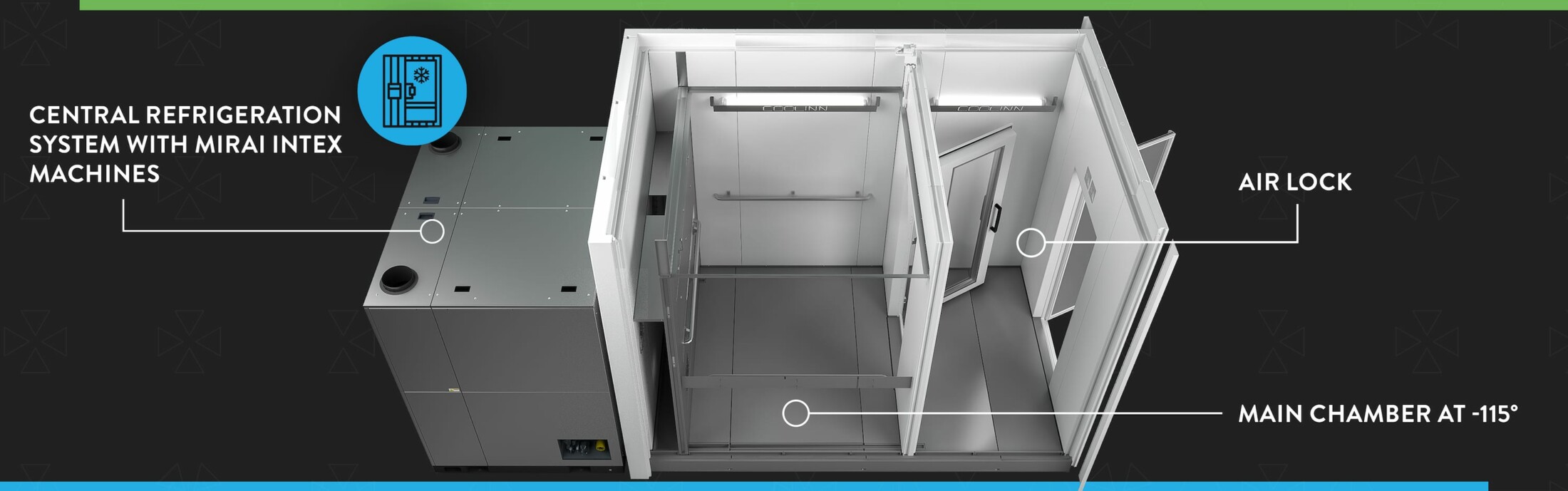

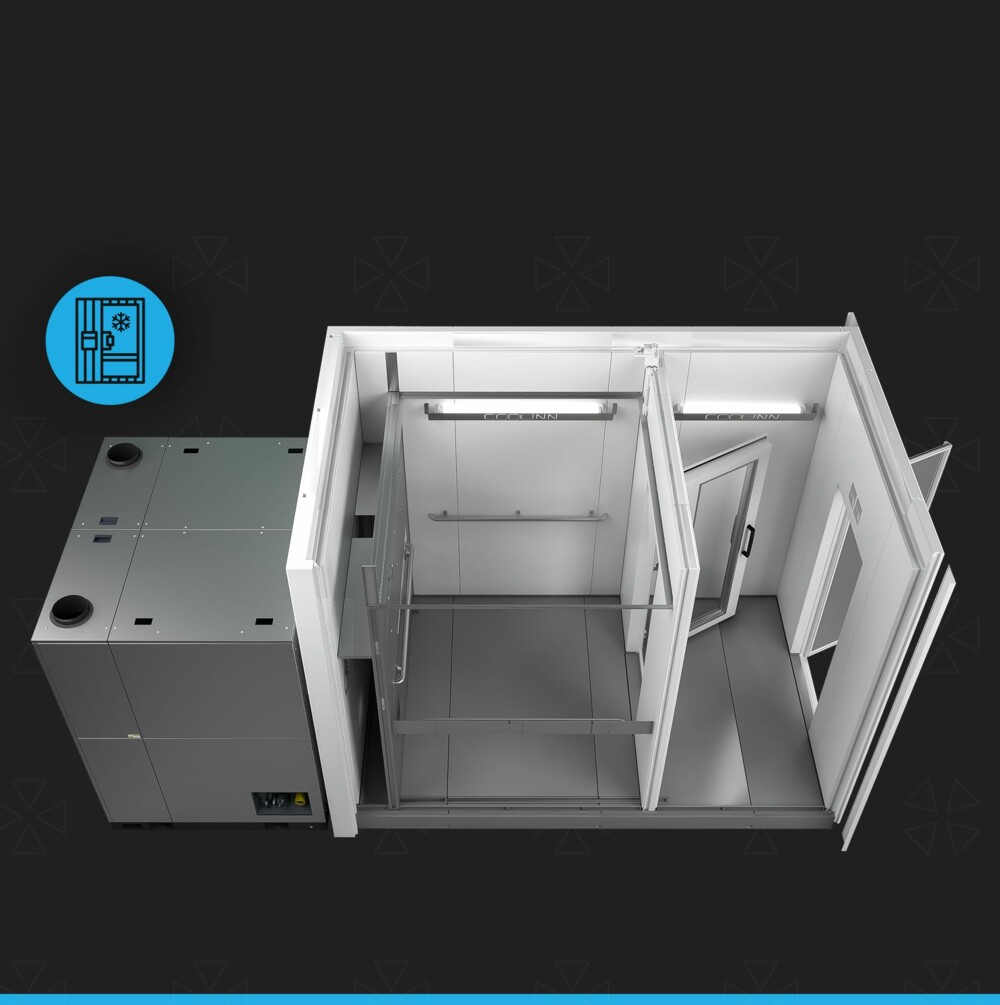

Turnkey individual full-body cold chambers with air (R729) as the refrigerant for flexible use from −40°C to −130°C - planned and implemented precisely to your requirements.

Turnkey individual full-body cold chambers with air (R729) as the refrigerant for flexible use from −40°C to −130°C - planned and implemented precisely to your requirements.

Cold has the physical property of sinking, which would cause the shins to be cooled the most, causing skin damage relatively quickly. The even air circulation within our full-body cold chamber creates a homogeneous temperature distribution from head to toe. However, the air speed is kept very low in order to provide the end customer with a particularly pleasant experience. Our temperature profile is unique on the market and provides the user with the maximum experience and the best possible cooling over the entire body.

The insulation is realized with tried and tested polyurethane insulation elements from Teledoor. Depending on the requirements, these can be optimized with integrated vacuum plates. When cold, the elements contract and the outer shell stays warm. This leads to mechanical stress, which is greater the higher the temperature difference and the height of the chamber. Our chambers are reinforced with hook locks in the chambers, so that the chamber is mechanically stable even after many temperature changes. In addition, we check all our installations with the thermal imaging camera and thus optimize penetrations and cable bushings.

A level floor is required for the floor construction. We can optionally also do this with screed work. The floor itself is equipped with non-slip, fully welded stainless steel sheets for easy cleaning.

The solution includes the complete control including control cabinet. The control is implemented via an S7 from Siemens and can optionally be equipped with a redundant H control, additional backup control and audit trail (GAMP 5). The control can be fully integrated into the building management system (GLT) with the classic interfaces. In addition, if necessary, faults can be detected and rectified at an early stage via remote maintenance.

The lighting is realized with robust special LEDs. In contrast to normal LED lights, these remain bright at low temperatures and can be switched on and off. This enables very efficient and safe operation. In addition, these are battery-buffered so that the room can be left safely even in the event of a power failure.

Reliable, durable, efficient and safe for people and the environment!

To cool the whole-body cold chamber, we use cold air cooling technology from Mirai Intex with only air (R729) as the refrigerant. With its mechanical de-icing, this ensures a homogeneous temperature distribution, dry room air with a dew point reduction of up to +20°C and constant temperatures without defrosting cycles.

Our whole-body cold chambers are characterized by non-slip floors, bright lighting and low ice formation and mechanical de-icing.

Air as a refrigerant is free, unregulated and safe. The cold chambers are robust and specially built for low temperatures.

Proven technology - Made in Germany. No interference from liquid refrigerant in the compressor or negative pressure in the system. Technology with very low wear.

The temperatures can be set from -115°C (optionally -130°C) to -40°C without additional add-ons or components.

Speed-controlled, no evaporator, expander with energy return to the turbo unit, low spec. Surface, vacuum insulation and lock.

All-natural refrigerant with no high pressures, no toxicity and no flammability. 0 GWP, 0 ODP, 0 TFA.

No leak test, air-bearing compressor = no wear, no oil. High quality insulation.